Mudlogging & Data Acquisition

- Surface Logging / Mudlogging

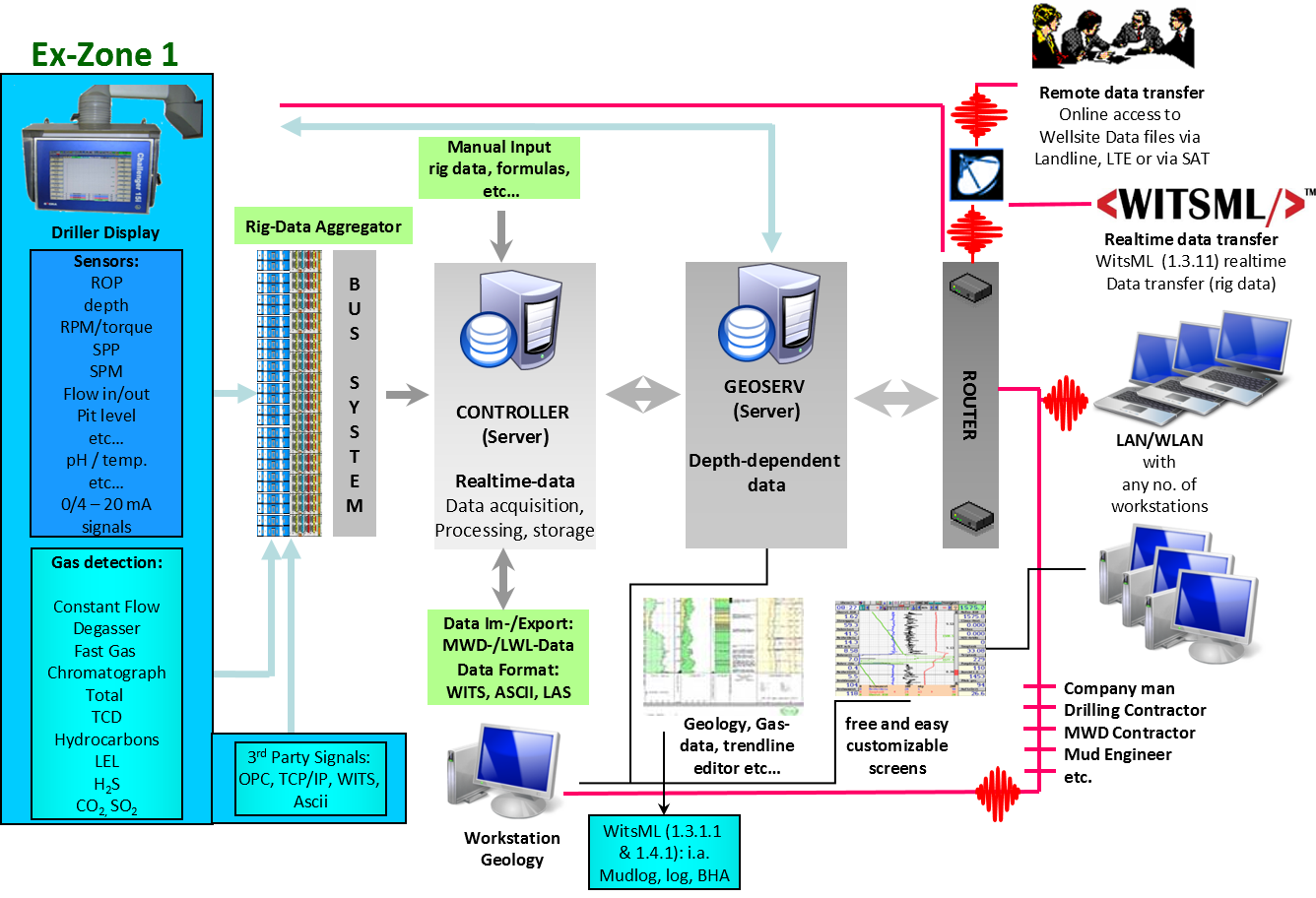

- Drilling Monitoring System (DMS) - Data Acquisition

- Realtime Gas Analysis

- Ambient Air Gas Monitoring

- Equipment & Sensors

- Sampling, Description & Special Testing

Surface Logging / Mudlogging

Data acquisition and recording of all surface parameters and sampling of rock cuttings is the base of mudlogging. A drilling fluid gas monitoring service and other measurements could be deployed if requested. If a further on-site processing is required, our Drilling-Monitoring-System with an extensive software-suite is available.

Lag corrected sample recovery, sample preparation and processing, lithological analysis and the stratigraphic field classifications of the samples are fundamental for the geological understanding and are part of our final documentation.

Further possible tests:

- oil show classification by UV light & oil cut

- automated analysis of the calcite / dolomite ratio (calcimetry with GEOCalcit™)

- determination of cutting / shale density

- sulfate testing

- micro fossil preparation

- caving monitoring

Range of Service

- data acquisition via Wits, WitsML, modbus TCP / IP & data integration of third-party data (e.g. MWD / LWD, cementing)

- sensor deployment (e.g. pit level, mud temperature, mud density)

- lag corrected cutting sampling & description

- technical & hydraulic calculations (e.g. swab & surge, ECD, bit optimization, drilling exponents: Dx, DxC, MSE, MSE-BPL)

- data visualization on the rigsite & remote (browser based)

- core handling, cutting (e.g. plugs, slabs), preparation (e.g. waxing) & logistics

- continuous documentation in the form of logs (e.g. mud logs, technical logs, pressure logs)

- reporting

- preparation & storage of sample material for further laboratory analysis

- photographic documentation of cores in reflected and transmitted light (e.g. salt cores)

Data Acquisition

Our Drilling Monitoring System (DMS) is able to acquire, process and display most data which are available on a rig site:

- drilling related technical data

- pit & pump data

- fluid / mud data

- geological & geochemical data

- reporting system / costs

- ambient gas-/ mudgas data

- MWD / LWL & wire line data

- cementing data

- hydraulic & performance data

We are able to acquire data from the rig data system itself (i.a. OPC modbus, TCP / IP, WITS, 4-20mA signals) and integrate these data seamless into our own independent measuring sensor setup. Furthermore we are able to intergrate WitsML data into our depth-based database.

Range of Service

- data acquisition, processing and visualization of all data measured at rig site in time- & depth-dependent databases

- realtime backup of all data

- realtime visualization on the rig site

- remote realtime data visualization

- application for depth- & timebased logs (i.a. masterlog, gaslog, techniclog, MWD-Log)

- pipe & casing management

- hydraulic calculations

- rig data aggregator and x-fer of WitsML data to any WitsML server (i.a. Kongsberg)

Realtime Gas Analysis from the Drilling Mud

One of the most important tasks carried out by GEO-data`s mudlogging service is the continuous measurement of a number of different gases, especially the monitoring of drilling fluid gases. This is carried out by extracting gas from the drilling fluid and passing through a series of gas detection instruments, which provides a detailed analysis of the extracted sample. Any gas detection system is dependent on the efficiency and reliability of the gas trap to remove the gas from the drilling fluid. GEO-data offers an enhanced design of a standard degasser and a constant volume degasser (CVD) according to your requirements. Beyond that, we are manufacturing our own GC’s, based on flame ionization detection (FID) for the reliable hydrocarbon detection.

Range of Service

- standard or constant volume degasser

- broad range of detectable gases: C1-nC5, H2S, CO2, N2, H2

- depth- & time-based recording and display

- threshold monitoring

- gas characterization (wetness, balance, character), pixler plots

- special gas sampling (e.g. IsoTubes™)

- reliable & field-proven gas chromatograph (FID) and TCD

Realtime Ambient Air Gas Safety Monitoring

A great hazard while drilling is the occurrence and emergence of explosive or toxic gas. It is our task to monitor the occurrence of dangerous gases at all times as well as alert all personnel on the rig site. We are providing zone 1 rated ambient air gas monitoring devices and different visual & audible alarm devices. To document the wind direction & speed we are providing special meterological sensors as well.

Range of Service

- LEL, H2S, SO2, CO2, O2 monitoring

- mercury vapor monitoring

- audible & visual alarm devices (siren, flashlights) with cutomizable sound and colour

- wind speed & wind direction

- gas safety monitoring following SIL 2 standard

Equipment & Sensors

We offer a broad range of sensors & equipment to monitor all surface related technical parameters (i.a. pressures, torques, revelations, weights, fluid levels, temperaturs, pH of mud, mudweights, conductivity of mud). Most sensors are Ex-rated and could be used in Zone 1 (Ex i, Ex e). Beside data acquisition with own sensors, we are able to receive and process most sensor signals from the drilling rigs itself (modbus TCP-IP, SPS S7, WITS, 4-20mA and others).

GEO-data is able to provide mudlogging containers (non-pressurized and pressurized) from 3m up to 9m length, which are equipped with a data acquisition & processing system. The interior is designed (6m and 9m container) to provide a safe and ergonomical working space for our field service personnel with a sample preparation area, sample description area and place for computers and other devises (i.a. GC-FID, alarm panels).

Range of Services

- provision of 3m, 6m and 9m field laboratories (non-pressurized & pressurized)

- data acquisition systems for own sensors, 3rd party signals (i.a. Wits, modbus TCP/IP)

- Zone 1 rated sensors according to your specifications

- receive & send data in Wits and WitsML format

- ambient air and mudgas monitoring

Sampling, Description & Special Testing

We are taking lag corrected cutting & gas samples. Our experienced personnel will process (cleaning, sieving) the cutting samples as per instruction of our client. A proper and detailed lithological description will be done and entered into our geological database to create i.a. logs. Special processing of cuttings for the determination of calcite/dolomite ratio, cutting density determination and further chemical analysis methods (i.a. alizarin red & sulfate test kit, UV luminescence of cuttings and oil, oil extraction with detergents) are part of our standard services.

Range of Services

- lag corrected cutting & gas samples (e.g. with Isotubes™, Isojars™)

- detailed lithological description & cutting photographs

- calcimetry, UV-Box, shale & cutting density, oil extraction, microfossil preparation

- reporting, log creation, pore pressure estimation, caving monitoring

- preparation of representative cutting-show column